Applications

Related Products

Benefits

Uniform, Non-Surging Feeder

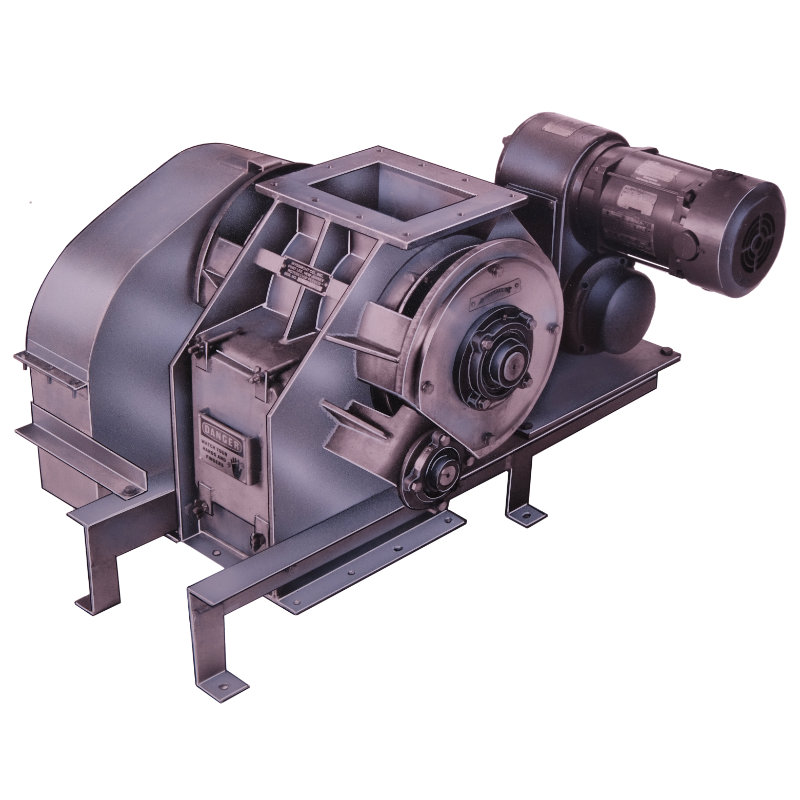

Komline-Wyssmont’s Multiple Screw Feeder features a series of carefully fabricated, continuously welded helicoids operating in parallel to feed material from a hopper without surging and bridging commonly experienced in ordinary screw feeders and conveyors. While most screw feeders and conveyors are known for surging and non-uniform feeding, Komline-Wyssmont’s Multiple Screw Feeder is specially designed to discharge with minimum surging. The variable pitch of the screw flights uniformly draws material from the hopper and resists segregation of the product.

Special fabrication and design can assure minimum breakage of crystals and pellets where this is specified. In sealed systems, the feeder will create its own seal under appropriate conditions.

Live-Bottom Bin

With an appropriately designed hopper above the screws, the unit becomes a live-bottom bin. It resists bridging and gently handles the material.

The Komline-Wyssmont Multiple Screw Feeder can be supplied in stainless steel, carbon steel, or special alloys. The housing can be jacketed to cool or warm the feed material.

Standard Features

- Totally enclosed AC motor

- Mechanical variable speed drive

- Sealed bearings

- “O”-ring shaft seals

- Sealed access door

- Sealed interlock on access floor

Optional Features

- Feed hopper

- PTFE non-stick coating

- nclined construction for elevating feed

- Explosion proof or Chemical duty

- PDC motor with SCR variable speed controller

- AC motor with VCF variable speed controller

- Safety interlock on drive guards

- Outboard bearings & stuffing box shaft seals

- Purged bearings or shaft seals