Applications

Related Products

Benefits

Key Benefits

- Achieve 90+% dry solids (99+% if desired )

- Produce Class A Biosolids for beneficial reuse of MWWTP sludge

- Achieve intermediate dryness for composting or combustion

- Reduce disposal cost

- Produce stable and marketable by-products

- Increase fuel value

- Re-process residuals and tailings

- Removal of hazardous volatile organic compounds (thermal desorption)

Features

- High thermal efficiency

- Low quantity of off-gas, facilitating easy permitting

- Cost effective and environmentally sound

- Easy to operate, requiring minimal attention

- Continuous process, no recycle required, no pre-conditioning of the feed

- Can be operated 24 hours per day or a portion of the day

- Safer than direct drying, low oxygen levels during operation

- Durable design, resulting in low maintenance

- Accepts a wide variety of feeds: slurry, paste, cake, granular, or powder

- Enclosed process eliminates fugitive emissions

- Heat transfer areas from 60 to over 3000 square feet (5.6 to over 279 square meters) per dryer

- Evaporation rates for biosolids applications from 500 to 10,000 lbs. of water per hour per dryer.

- System capacities for small, medium and large plants

- Indirectly heated with steam or circulated thermal fluid (hot oil)

- Compact installation

- High turndown ratio with no loss of thermal efficiency

- Designed, constructed, and tested per ASME Code or PED

- Carbon steel, stainless steel, or alloy construction

- Abrasion-resistant hard-surface coatings are available

- Robust design, providing for high torque and low operating speed

- No internal parts to adjust or maintain

- Shafts, bearings, and drive components are designed for long life under adverse conditions, ensuring long-term mechanical integrity

- Control integration provided by K-S

Design

The K-S Paddle Sludge Dryer provides a reliable and efficient method for drying filter cakes and centrifuge concentrates. The K-S Paddle Sludge Dryer is indirectly heated using steam or circulated thermal fluid (hot oil). High-energy efficiencies and low off-gas volumes are characteristics of a K-S Drying System.

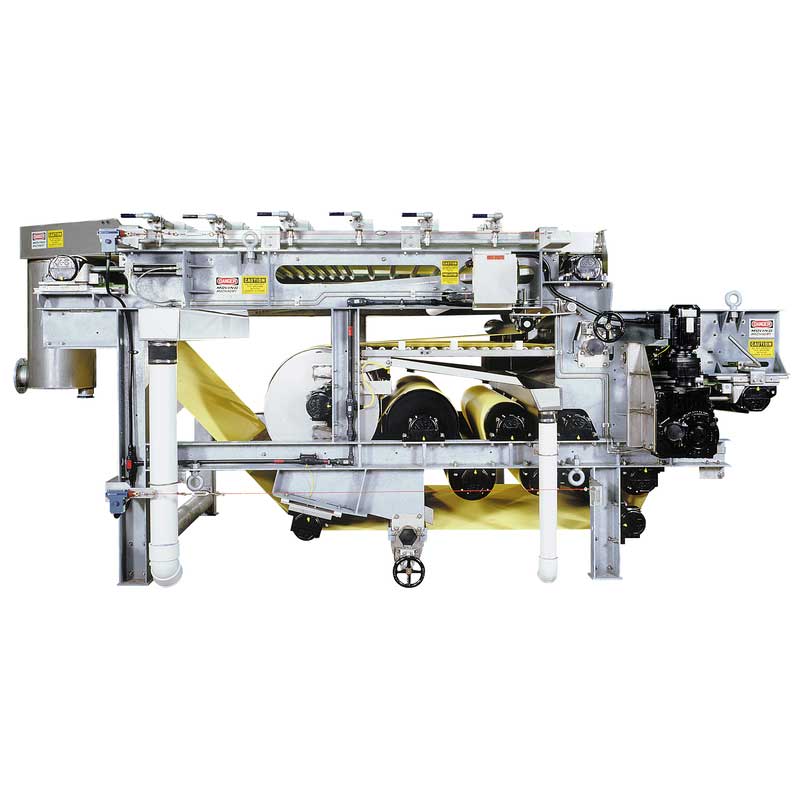

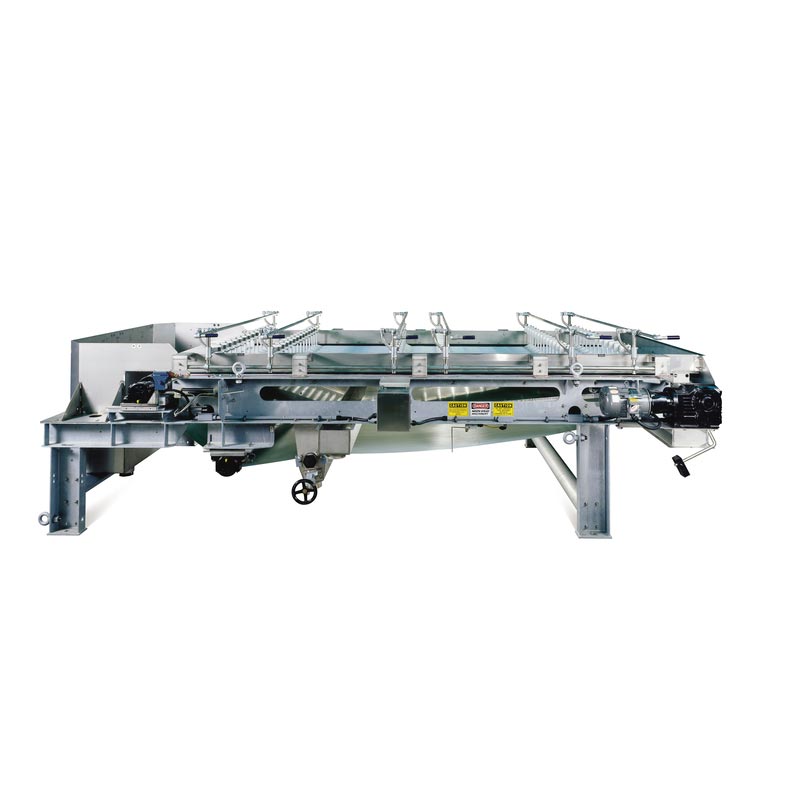

The K-S Paddle Sludge Dryer is an indirect heat transfer device that utilizes mechanical agitation to enhance contact with the product being dried. Dual counter-rotating shafts with unique intermeshing wedge-shaped paddles produce intimate mixing, optimize heat transfer, and provide a self-cleaning effect.

A large heat transfer area to volume ratio is achieved by the use of heated hollow paddles and a jacketed trough, through which the heating medium flows. This results in a compact machine requiring less space and having lower installation cost than alternate drying technologies.

Indirect dryers have a metal wall that separates the process mass from the heat source. High thermal efficiency is obtained because the heat from the heating medium goes directly into the process mass. As the material comes into contact with the heated trough and agitators, the process mass is heated via conduction. The insulated dryer has very little heat loss.

The K-S Paddle Sludge Dryer transports material, regardless of its handling characteristics. The dryer easily accepts feeds with a wide range of feed solids concentrations. Pre-conditioning the feed by mixing with recycled dried product, to make it conveyable is not required.

This results in a safer operation and lower capital, operating, and maintenance costs.

Material is conveyed through the K-S Paddle Sludge Dryer by displacement. As material is added to the dryer, it is assimilated into the bed by the mixing action of the agitators. Hydraulic head pressure, combined with the action of the wedge-shaped paddles, pushes material around the paddles.

As sludges dry they go through a number of transitions in handling characteristics. These changes are directly related to the solids content. For example, extremely wet sludges and extremely dry sludges require substantially less torque than sludges in the plastic-sticky-phase, when high torque is required. The K-S Paddle Sludge Dryer is designed with high torque capabilities to increase its process flexibility. Extra torque keeps you on-line, even during upset conditions.

No external sweep gas is required. Exhaust gas is minimal and at a low temperature. Therefore, the volume of non-condensable gas from the dryer that may require treatment for odors is minimal.

K-S process and project engineers provide assistance at all phases of the project. Depending on your specific requirements, K-S can provide you with a dryer, or a complete system.

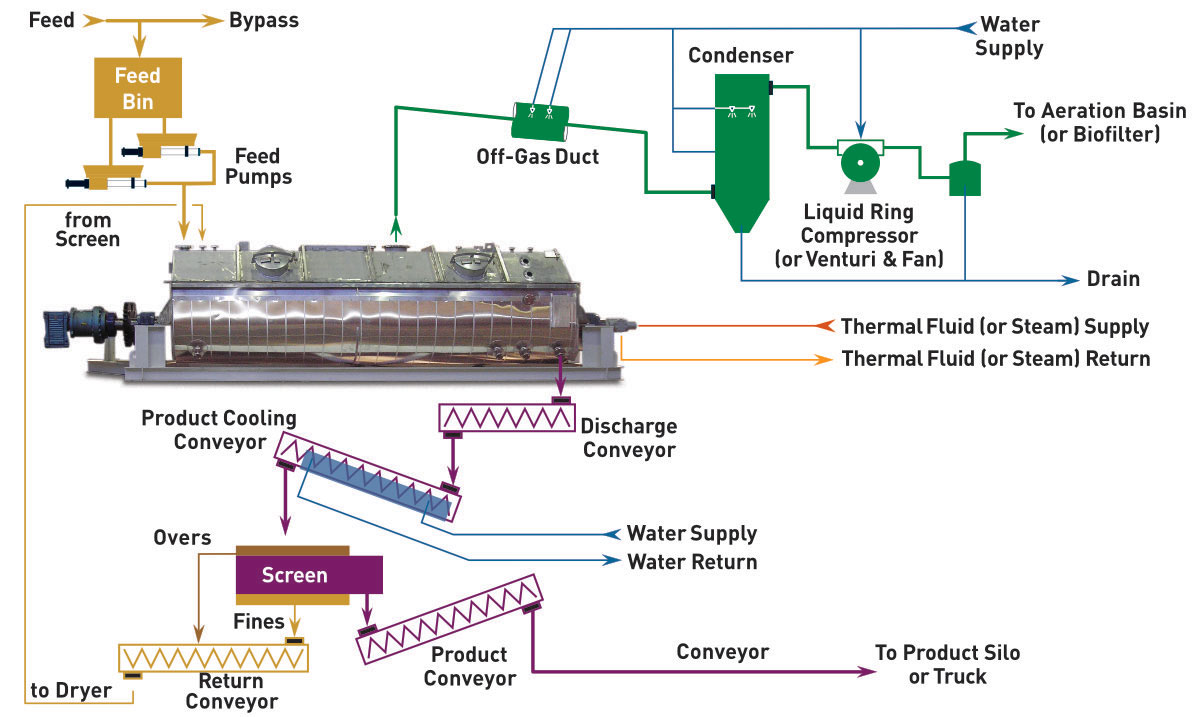

System

A successful plant depends on the integration of the key process units with properly selected ancillary equipment and the right facility design. Reliability, ease of operation, rugged construction, proven performance, and superior customer service are all hallmarks of a K-S installation.

Safety features must be part of the system design. The indirectly heated K-S Paddle Sludge Dryer operates with an inert low temperature environment. Gas (air) is not used to convey a hot product in the dryer. The totally enclosed process eliminates fugitive emissions.

Low temperature operation creates a safer operation when processing combustible materials. For inert material and for thermal desorption higher temperatures are used.

When needed deflagration vent panels are incorporated into the dryer cover. These are ducted outside of the building. An automatic water deluge system can be incorporated into the dryer to cool combustible material, in the event of a high temperature condition. Inerting the dryer with inert gas is also an option.

Videos

K-S Paddle Dryer Process Overview

This video is of an actual pilot test drying biosolids. Clearly shown are the various phases of drying: wet cake, plastic, shearing, wet granular, and dry granular. Being able to handle all phases of this process is what makes our dryer unique.

Paddle Dryer Features Overview

This video shows an overview of the K-S Paddle Dryer/Processor, its function, and the wide array of options available to fit your needs.

Paddle Dryer Model

Our model unit is shown rotating with plastic beads to demonstrate the mixing action of our dual, counter-rotating agitators.

FAQs

Q:

What are the energy requirements for drying?

A:

The energy requirements vary depending on the feed moisture content, the final dryness desired and the choice of heating mediums (steam or thermal fluid)

Example: Our dryer needs 1155 BTU per pound of water removed to dry material from 20% ds to 90% ds. If a steam boiler is used the boilers efficiency is typically 80%. Thermal fluid heaters can have thermal efficiencies of 80% to 88% depending on design. Energy recovery should be considered if the plant has hot stack gases.

Q:

How is the dryer/processor sized?

A:

The hourly feed rate is determined and the total hourly heat load calculated (Q). The heating/cooling medium temperature establishes the log mean temperature differential (driving force, LMTD). The heat transfer coefficient (U) is dependent on the material being dried. This is established by using data from prior experience and test data. With these variables established, the heat transfer area (A) is calculated by:

A=Q(U⋅LMTD)

Q:

What does a drying system cost?

A:

K-S Applications Engineers can quickly provide an estimate for your plant. We need to establish the hourly feed rate to the dryer, the feed solids level and the desired product characteristics. Complete the Applications Questionnaire and send it in for an evaluation or call us.

Q:

What heat transfer medium temperatures are typically used?

A:

For drying of most combustible materials we limit the heating medium temperature to 380 to 400°F. For heat sensitive materials much lower temperatures are used. When low heating temperatures are used a larger dryer is required. For drying of inert materials and for thermal desorption much higher heating mediums temperatures are used (up to 750°F).

Q:

Does K-S offer lab and pilot testing?

A:

Yes, K-S can provide pilot testing at our Technical Center or at your plant. Contact us for more information.