Applications

Related Products

Benefits

Benefits

Self priming with ability to handle suction- fts and entrained gases

- Positive displacement

- Can run dry without damage

- Flow rate is not system head dependent

- Flow rate is not sludge concentration dependent

- Positive metering

- High volumetric efficiencies, 90% and higher

- No critical tolerances

- Flow rate consistent throughout life of pump

- Easy clean out capability

- Large internal clearances

- Handles high solids concentrations

- Built-in overload protection

- Low cost of maintenance

- Common replacement parts are easily accessible

Design

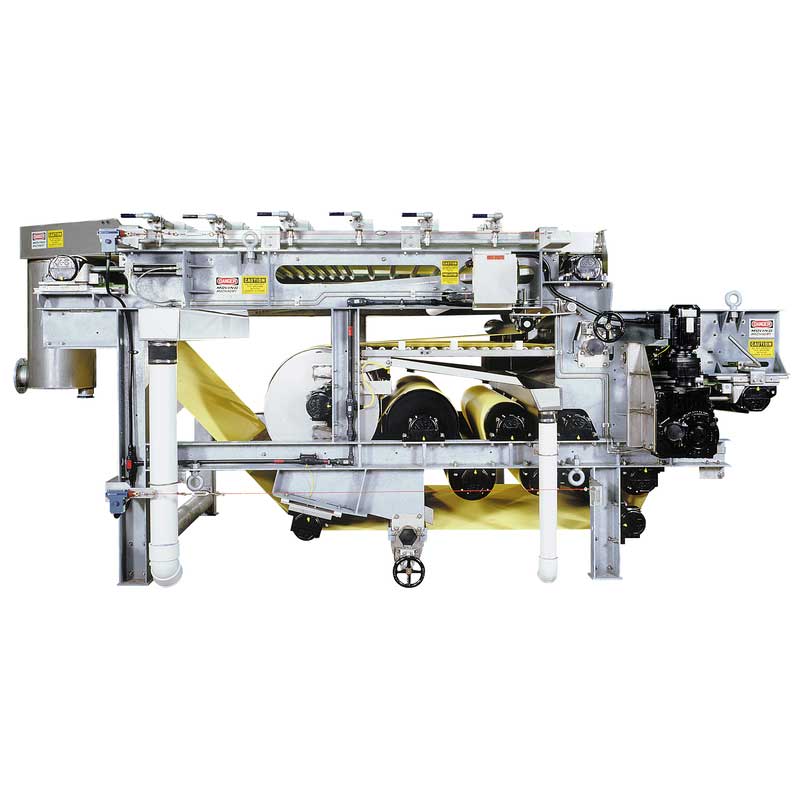

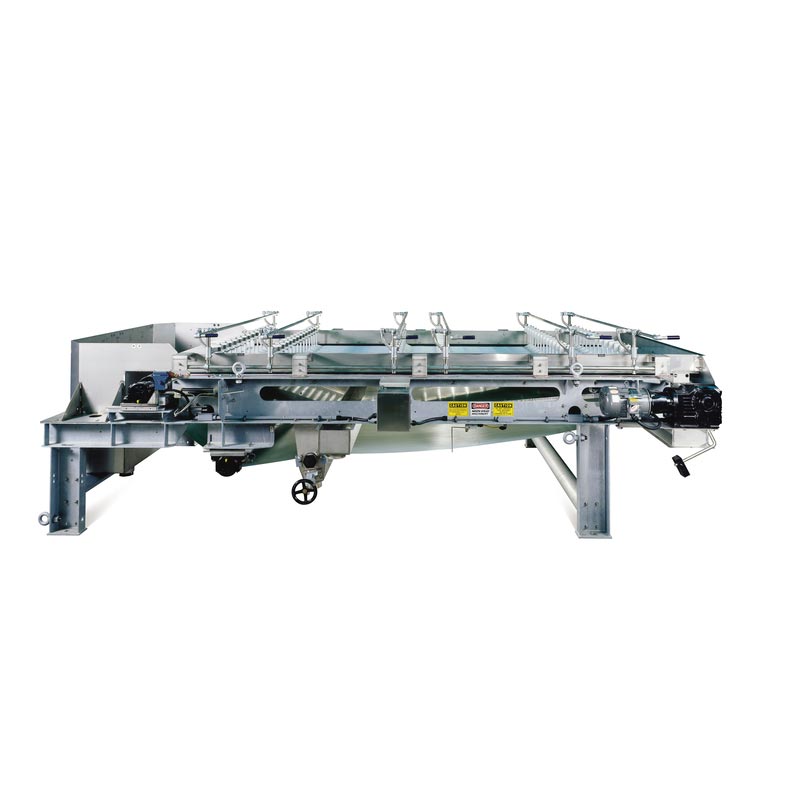

- Units are available as simplex, duplex, triplex and quadruplex designs for flow rates up to 550 GPM and heads up to 300 ft.

- Constructed of heavy duty 30,000-40,000 close grained iron which enables operating pressures up to 130 psi and hydrostatic test pressures up to 200 psi

- Fully sectionalized design for easy repair and replacement of parts

- Adjustable eccentrics for altering stroke length and providing overload protection

- Rigid 2″ base plate design with 12″ bearing pedestals which greatly reduces maintenance time involving alignment

- 4-bolt roller bearings for greater bearing- fe and strength

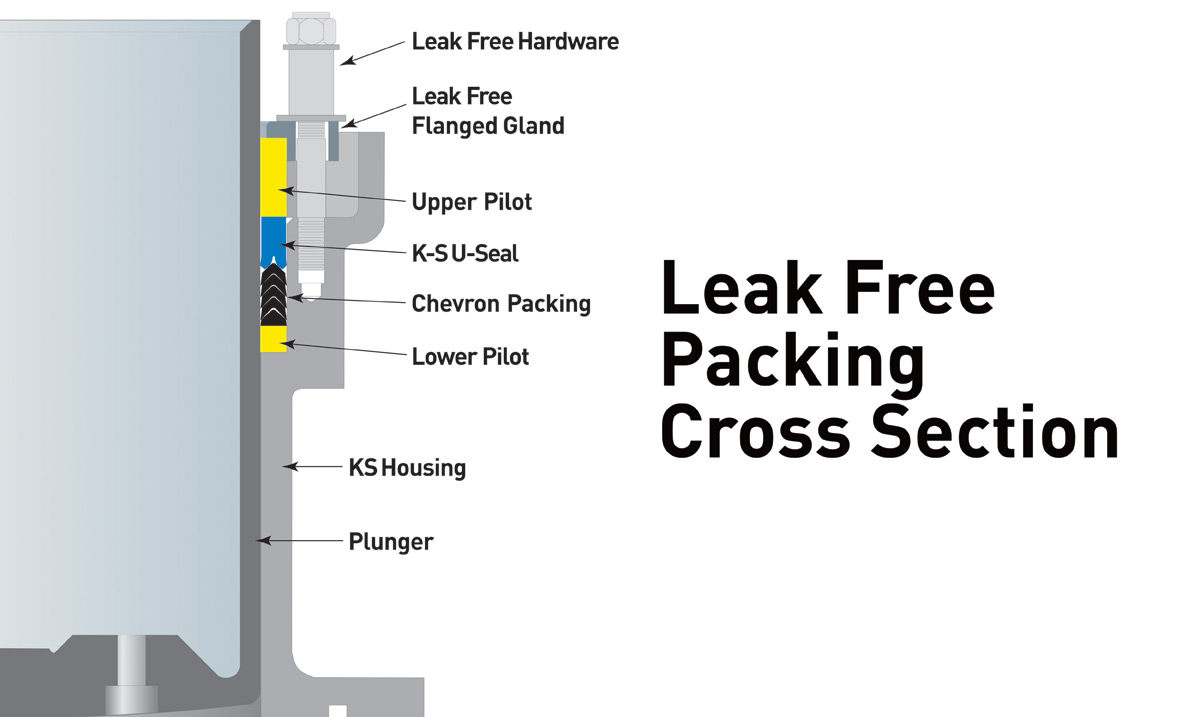

- Patented “Leak Free” packing designed to eliminate or drastically reduce the leakage commonly associated with plunger pumps.

- K-S introduced the separate and replaceable eccentric liners which reduce cost and maintenance time

- Hardened cast iron plungers available as standard with harder ceramic coatings and tungsten carbide coated plungers available for the most severe applications.

- K-S exclusive direct drive cycloidal arrangement that eliminates backlash commonly associated with other gear boxes or drive arrangements

- Valve chamber with easily accessible valve seats of cast iron, stainless or rubber construction

- Our KSK design is ideal for areas where space is limited. 18″ is the maximum width when the pump is set up in an in-line arrangement.

System

- Automated lubrication systems involving either an electric solenoid oiler or a shaft driven, mechanical force feed oiler.

- Mechanical or variable frequency speed control

FAQs

Q:

Why a plunger pump?

A:

When the application requires a suction lift or moving heavy sludges that involve head requirements that can bog down other types of sludge handling pumps.

Q:

Can the pump handle a suction- ft?

A:

Plunger pumps are self-priming pumps and can reprime a suction line up to 15 ft and pull suction lifts up to 20 ft but these numbers are based on water and the pump located very close to the source. (Note: The higher the sludge concentrations the lower the suction lift capabilities.)

Q:

Why is the flow rate unaffected by the system head?

A:

A plunger pump is a positive displacement pump and its performance curve is a nearly vertical line. When a plunger pump is set to do 100 GPM, it will try to do that flow rate whether it is pumping against 10 ft of head or 300 ft of head. Only the horsepower will vary.

Q:

Does your “Leak Free” packing really work?

A:

K-S has put many engineering hours into its patented packing design, which involves stabilizing the plunger to move in only the vertical direction. This, in turn, allows for better sealing of the packing against the plunger.

Q:

We have noticed marked reduction in the leakage associated with plunger pumps and for extended periods of time.

A:

Grit is still the biggest problem to the life of the packing and the plunger but this can usually be overcome by enhancing the materials of construction to more abrasion resistant materials such as ceramic or tungsten carbide coating plungers.